Metal and alloy wire meshes are used in the formation of broad range of industrial filtering, sieving and screening equipments that are used in the variety of applications. Few of them are described as following:

Twist set for melt sieves: While the production of synthetic fibers, it is crucial that unwanted particles do not hinder the very fine spinnerets. For this, special sieving based on Dutch Weaves with a twilled dutch, reverse or reverse twill meshes are used that can cover sieving range about 40 to 500 micron.

Diesel Soot Filters: To meet the strict emission control needs that come into force for diesel based commercial automobiles, new exhaust gas purification equipments need to be installed. Our special wire mesh filters will retain over 99% critical microparticles about 10 to 1000nm.

Superior quality rotary screen printing: Rotary screen printing is emerging as the technology of choice for operations of label printing. Important for the high reproduction of this printing is the basic quality of wire mesh that is utilized for the stencil holder. Heanjia SuperMetals use ultrafine quality wiremesh clothes that are mechanically very strong as well as nickel plated.

Acoustic Absorbers: An outstanding choice of controlling the aircraft noise is to keep the engines at the silent mode. The advanced composites for acoustic screens absorb noise within the metal wire mesh clothes are an essential part in the composite for comprehensive acoustic absorbers.

Aircraft lighting security: The aeronautics industry is regularly striving for lighter and more reliable materials. Therefore fiber composites constructed from strengthening wire meshes and synthetic resins are used. To offer security from lightning, we have produced a special wire mesh cloth that is utilized in the prepregs for engine shielding and in other various parts of helicopter such as nose cones, front edges of wings and rotary blades.

Electromagnetic interference Prevention: The electronic devices like computers can be easily troubled due to electromagnetic interference.The solution is EMI or RFI shielding- the screening of equipments, housings,systems and whole rooms. The uniformity of our wire mesh clothes and the different kinds of perforations introduced with the combination of mesh size, wire gauge and material, a suitable solution for each type of screening application is fabricated.

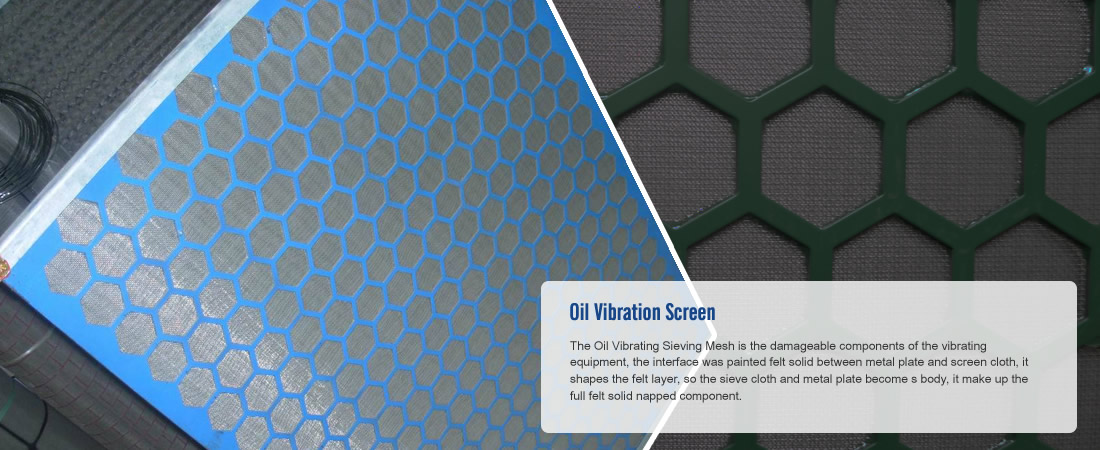

Anti-clogging, fine and excellent sieves : Finer size of the granules that need to be filtered the higher the probability of sieve mesh is clogged. Our vibration frame sieves solve this trouble by particular excitation springs that rapidly increase the sieve mesh to avoid clogging and hence guarantee an improved screening functionality.

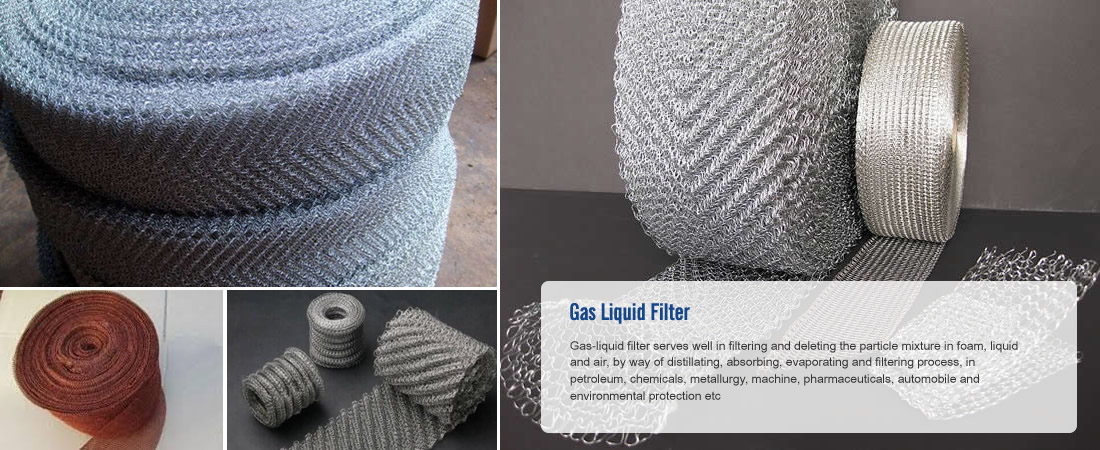

Filter candles to filter systems: The demands for filtering processes are as crucial as these vary. A broad range of industries with specifically produced filter candles and full fledge filtering and precipitation units complete with our entire essential filter system components.

Sand control equipments for offshore applications: The pollutants in the oil pipelines with sand grains are a critical problem while using deep sea wells. The high quality stainless steel 316L wire mesh filter clothes are used for oil industry equipments for advanced sand control systems.